4-3: Equipment

The Federal Aviation Administration of the U.S. Department of Transportation, which publishes the Federal Aviation Regulations (FARs), regulates the design, maintenance, and alteration of parachute equipment.

All skydivers should be familiar with the following FARs and their applicability to skydiving (see Chapter 2-3 and 2-4 of this manual):

- Part 65—Certification of Parachute Riggers

- Part 91—General Flight Rules

- Part 105—Parachute Operations

- Advisory Circular 105-2—explains in detail various areas of parachute equipment, maintenance, and modifications.

The FAA grants approval of parachutes to manufacturers in the form of Technical Standard Orders (TSOs). TSO C-23 is issued to parachutes that comply with the current performance standards.

- NAS 804 for TSO C-23b

- AS-8015A for TSO C-23c

- AS-8015B for TSO C-23d

These standards specify the tests that a parachute system and its component parts must pass to receive approval for civilian use. FAR Part 21 contains the procedures for obtaining TSO approval.

Only those with FAA approval may perform alterations to approved parachutes. Approval may be obtained by submitting a request and description of the alteration to the manufacturer or to an FAA Flight Standards District Office. An FAA master rigger and a manufacturer with an approved quality-assurance program are eligible to receive alteration approval. Alterations may not be performed without full documentation of FAA approval for the specific alteration.

Jumpers should choose canopies that will provide an acceptable landing in a wide range of circumstances by considering several factors including canopy size, wing loading, planform (shape), skill level, and experience. Owners should verify with a rigger that their gear complies with all applicable updates and bulletins.

Jumpers should observe the canopy manufacturer’s recommendations for the correct canopy size, which usually includes maximum recommended weight with respect to the jumper’s experience, drop zone elevation, and conditions such as density altitude.

Wing loading, measured as exit weight in pounds per square foot of canopy size provides only one gauge of a canopy’s performance characteristics. A smaller canopy loaded equally to a larger one of the same design will exhibit a faster and more radical control response, with more altitude loss in any maneuver. Design, materials, and construction techniques can cause two equally loaded canopies to perform very differently. Different planforms (square vs. elliptical) exhibit very different handling characteristics.

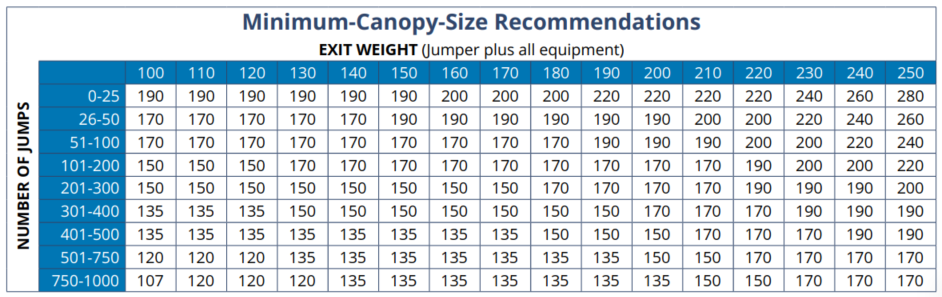

The Minimum Canopy-Size Recommendations chart provides the minimum recommended canopy size by taking exit weight and the number of solo-equipment jumps made with square parachutes into account. A student’s canopy size is at the discretion of

the instructor. Due to the varied sizes of canopies from different manufacturers, any canopy less than 3% smaller than the listed

recommendation is acceptable. Canopy choices for jumpers who have made more than 1,000 jumps is at their own discretion.

These minimum-canopy-size recommendations may be too aggressive for some jumpers and, in other cases, too conservative.

Instructors, canopy coaches and drop zone leadership should assist skydivers in selecting a canopy appropriate for their ability

and progression. The USPA Downsizing Best Practices Card, available at uspa.org/downsize, is a valuable self-assessment tool.

All skydivers should use a steerable reserve canopy. The FAA requires that the reserve parachute assembly—including harness, container, canopy, risers, pilot chute, deployment device, and ripcord—are approved.

Jumpers must observe FARs regarding the manufacturer’s maximum certificated weights and speeds for parachutes. Parachutes approved under FAA Technical Standard Order C-23b, C-23c, and C-23d are subject to different testing standards and operation limits. The entire parachute system is limited to the maximum certificated load limit of the harness-and-container system or reserve canopy, whichever is less. Load limits are found in the owner’s manual, the manufacturer’s website, or placarded on the parachute component itself.

For a ram-air reserve, jumpers should not exceed the maximum suspended weight specified by the manufacturer (not necessarily the maximum certificated load limit). A jumper may exceed the rated speeds of a certificated parachute system (harness and/or parachute) by jumping at higher MSL altitudes or falling in vertical freefall orientations.

A round reserve canopy should be equipped with a deployment device to reduce the opening force and control deployment, should have a rate of descent that does not exceed 18 feet per second (fps), and must not exceed a rate of descent of 25 fps at sea level conditions (NAS 804). The following scale indicates the minimum size round reserve canopy recommended for use according to the exit weight of the skydiver:

| Total Suspended Weight* |

Recommended Equivalent Descent Rate

(high-porosity flat circular)

|

| Up to 149 pounds | 24-foot |

| 150 to 199 pounds | 26-foot |

| 200 pounds and over | 28-foot |

*The use of lower-porosity materials can reduce the rate of descent.

The FAA requires the harness of a dual parachute assembly to be approved. All harness ends should be folded over and sewn down or wrapped and sewn down to prevent the harness from unthreading through the hardware during parachute deployment.

Canopy-release systems should be maintained according to the schedule and procedures in the owner’s manual. The location of operational handles should align with the manufacturing industry’s standardized locations. The harness should be equipped with single-point riser releases (one handle releases both risers) for easy and rapid disengagement from the main canopy.

Loop-type reserve handles should be made of metal. Plastic and composite reserve handles are not recommended. Jumpers should practice peeling and pulling pillow-type reserve handles until certain they can operate them easily in an emergency.

All ripcord-housing ends should be secured. Ripcord pins, when seated, should either be started inside the housing or clear the closing loop before entering the housing. A ripcord-cable stop should not be used; fatal accidents caused by reserve entanglements with ripcords secured in this manner have been documented.

The reserve system is usually designed to use a specific type of pilot chute. The reserve pilot chute should be properly seated in the container and repacked if it has shifted.

Deployment brake systems should provide secure stowage of the steering toggles and slack brake line to prevent brake-line entanglements and premature brake release.

The main pilot chute is part of the main parachute system. Pilot chute size can affect the opening characteristics of the main canopy.

Spring-loaded and hand-deployed pilot chutes of both types (throw-out and pull-out) each have strengths and weaknesses that affect the user’s emergency procedures and other decisions.

On throw-out hand-deployed systems, the pilot chute and pouch size must be compatible. Collapsible pilot chutes add complexity and have more required maintenance since forgetting to set or cock the pilot chute can cause a high-speed pilot-chute-in-tow malfunction, and the moving parts create additional wear to the system.

F. Reserve Static Line (RSL) and Main-Assisted-Reserve-Deployment (MARD) Device

With very few exceptions, USPA recommends that jumpers use a reserve static line (RSL), a backup device that automatically initiates reserve deployment when a jumper cuts away. Preferably, the RSL is equipped with a main-assisted-reserve-deployment device (MARD). RSL use is mandatory for students. Though RSLs (with or without MARDs) are proven lifesavers, jumpers should never rely on them to initiate reserve deployment and must manually pull the reserve ripcord immediately after a cutaway.

On an RSL-equipped rig, one end of the RSL lanyard attaches to a main riser, and then the lanyard runs to the reserve ripcord cable, where the other end attaches. When the main risers depart following a cutaway, the RSL lanyard pulls the reserve pin and releases the reserve pilot chute, which deploys the reserve parachute. When the RSL includes a MARD device, the RSL lanyard hooks to the reserve-pilot-chute bridle, which allows the departing main parachute to assist in extracting the reserve, speeding up its deployment. RSLs help to both ensure and speed up reserve deployment when fractions of a second matter; MARDS speed up the deployment even further.

RSL vs. MARD-Equipped-RSL Reserve Activation:

Reserve activated via a traditional RSL (left) and a MARD-equipped RSL (right).

Photo by Niklas Daniel of AXIS Flight School.

An RSL, with or without a MARD, may also incorporate a Collins lanyard. This lanyard attaches to the reserve static line and is designed to release the non-RSL-side riser in the event the RSL-side riser breaks or disconnects prematurely. Consult a rigger for more information.

USPA recommends an RSL, preferably with a MARD, for all experienced jumpers with the possible exception of those attempting linked canopy formations. If temporarily disconnecting an RSL, take care to ensure it doesn’t interfere with the operation of the parachute system; consult a rigger.

When misrouted or attached incorrectly, these safety devices may not function and can even complicate or prevent a cutaway. Unless the manufacturer’s instructions state otherwise, do not use a connector device between the left and right main risers.

G. Automatic Activation Device (AAD)

USPA encourages all licensed skydivers to use an AAD—a device that initiates reserve deployment when the jumper reaches a preset altitude and descent rate—and requires its use for student skydivers. An AAD is only a backup device, and no jumper should rely on it to deploy a parachute. Those who use one and are educated on its function are significantly more likely to survive loss of altitude awareness or consciousness during a skydive.

The FAA requires those who use an AAD to maintain it in accordance with the manufacturer’s instructions (FAR 105.43.c). Each jumper should read and understand the owner’s manual for the AAD.

An AAD may complicate certain situations, particularly if the jumper deploys the main parachute low enough for the AAD to activate. Understanding and reviewing the emergency procedures for two canopies out (SIM Chapter 4-1) is essential.

Note: AADs may also be used with main parachutes, but this occurs only in specialized circumstances.

H. Static Line (Main)

The FAA requires static-line deployment to be either by direct bag or pilot-chute assist. The direct-bag method reduces the chance of the student interfering with main-canopy deployment. The pilot-chute-assist method must use an assist device according to FAR 105.47. The assist device must attach at one end to the static line so that the container opens before the device is loaded, and at the other end to the pilot chute. The FAA requires the pilot-chute-assist device to have a load strength of at least 28 but not more than 160 pounds.

The static line should attach to an approved structural point of the airframe. A seatbelt attachment point is considered part of the airframe, but the static line should pull on it in a longitudinal direction. Aircraft seats are not considered part of the airframe.

Static-line construction should include:

- a length of at least 8 feet but not more than 15 feet and should never come into contact with the aircraft’s tail surfaces

- a locking slide fastener, ID number 43A9502 or MS70120

- webbing of not less than 3,600 pounds tensile strength

I. Borrowing or Changing Equipment

No one should rent or loan a parachute to persons unqualified to carry out an intended skydive or of unknown ability. The use of unfamiliar (borrowed or new) equipment without sufficient preparation has been a factor in many fatalities. Whenever possible, avoid or minimize changes in equipment type during student training or when borrowing equipment. Any jumper who makes equipment changes should receive adequate transition training.

When jumping a new or different main parachute, a jumper should follow the recommendations in Chapter 5-9C: Downsizing Progression.

J. Use of Altimeters

Skydivers must always know their altitude and may choose to use a combination of altimeter types to maintain altitude awareness during all phases of a skydive. Common altimeter types include digital and analog altimeters that can be worn on the wrist or chest strap, as well as audible altimeters worn in or on a helmet.

Altimeter Errors

All altimeters use electronic and/or mechanical components that are subject to damage and may fail in use. You can expect minor differences in indicated altitude, so turn on or zero the altimeter at the landing area and do not re-adjust the altimeter after leaving the ground. Altimeters may lag during both ascent and descent; expect inaccuracies of up to 500 feet, plus or minus. The needle of an analog altimeter can also stick during both ascent and descent.

When an altimeter is in a burble (as when the jumper is falling back-to-earth), it may read inaccurately. To prevent damage that can cause accuracy errors, handle altimeters with care and maintain and store them according to the manufacturer’s instructions.

K. Accessories

Weather, drop zone conditions, the proficiency of the skydiver, and the skydiver’s experience with the type of jump they will be performing should determine the use of personal equipment. Jumpers should wear adequate protective clothing, including jumpsuit, helmet, gloves, goggles, and footwear for all jumps, with the possible exception of intentional water landings. Gloves are essential when the jump-altitude temperature is lower than 40° F.

A jumper should carry a protected but accessible knife. All skydivers using solo equipment should wear a lightweight, rigid helmet that does not restrict vision or hearing. All jumpers should wear flotation gear when the intended exit, opening, or landing point of a skydive is within one mile of an open body of water (defined as one in which a skydiver could drown).

L. Main Parachute Packing

The main parachute of a dual assembly may be packed by—

-

an FAA rigger

- An FAA rigger may supervise other persons in packing any type of parachute for which that person is rated (FAR 65.125.a and b).

- A non-certificated person may pack a main parachute under the direct supervision of an FAA rigger (FAR 105.43.a).

- the person who intends to use it on the next jump (FAR 105.43.a)

Each individual skydiver should have the written approval of an S&TA, USPA Instructor or Examiner, or an FAA rigger to pack their own parachute. All parachute packers should know and understand the manufacturer’s instructions for packing, maintenance, and use.

Tandem main parachutes may be packed by (FAR 105.45.b.1)—

- an FAA rigger

- the parachutist in command making the next jump with that parachute

- a packer under the direct supervision of a rigger

Exercise extreme caution when using temporary packing pins.

M. Parachute Maintenance

The equipment owner should frequently inspect equipment for any damage and wear. A qualified person should promptly correct any questionable condition. The Equipment Section of Category G of the USPA Integrated Student Program details owner inspection of the parachute.

Maintenance and Repair of the Reserve

The FAA requires the entire reserve assembly to be maintained as an approved parachute. Only an FAA-certificated parachute rigger may do repairs to the reserve assembly.

Maintenance and Repair of the Main

An FAA-certificated rigger or the owner (if he or she has adequate knowledge and skill) may perform repairs to the main. The main parachute and its deployment bag and pilot chute need not be maintained as “approved.”

Major repairs and alterations may be performed only by or under the supervision of an FAA Master Rigger, the parachute manufacturer, or any other manufacturer the FAA considers competent.